In the grand quest for sustainable waste management, the intersection of technology and innovation has birthed a transformative process – the plastic pyrolysis machine. As we unravel the intricate tapestry of converting plastics into fuel, the alchemy of pyrolysis takes center stage. This exploration delves into the depths of this technology, its nuances, and the promising avenues it opens for a circular economy.

The Essence of Plastic Pyrolysis:

Pyrolysis Unleashed:

At its core, plastic pyrolysis is a thermal decomposition process that breathes new life into discarded plastics. Without the constraints of oxygen, plastics undergo a metamorphic journey, breaking down into valuable hydrocarbons. The magic happens within the confines of the plastic pyrolysis machine, where controlled heat becomes the catalyst for transformation.

Catalyzing Change:

Some plastic pyrolysis machines integrate catalysts, molecular maestros that steer the pyrolytic reactions. Zeolites, metals, or acid-based catalysts become silent orchestrators, enhancing the efficiency and yield of the process.

Unraveling the Technological Marvel:

Cracking the Code:

The heart of the plastic pyrolysis equipment lies in its ability to crack the complex polymer chains present in plastics. High temperatures initiate the cracking process, unraveling the molecular structures and paving the way for the creation of valuable byproducts.

Distinct Stages:

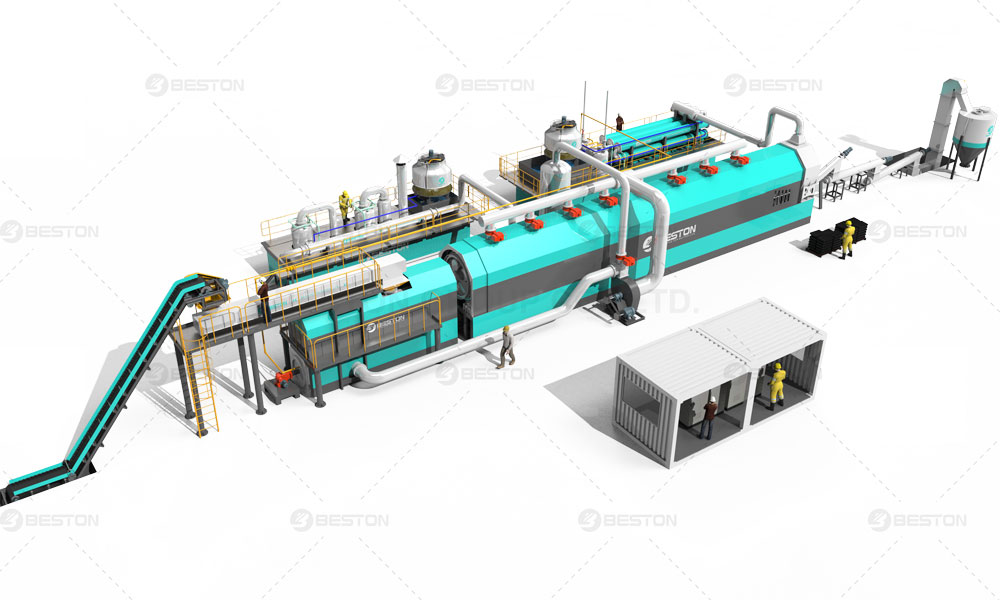

The pyrolysis journey unfolds in distinct stages within the machine:

- Preheating: Plastics are preheated to the desired temperature, preparing them for the pyrolytic reactions.

- Pyrolysis: Thermal decomposition occurs, leading to the production of gases, liquids, and solid residues.

- Condensation: Gases are condensed into liquid form, yielding valuable fuel.

- Solid Residue Collection: The remaining solid residues, often carbon black, find applications in various industries.

Beyond Waste Reduction: Plastics Transformed into Fuel

Liquid Gold:

The primary output of the plastic pyrolysis machine is a liquid treasure – a mixture of hydrocarbons that can be refined into fuel. This liquid gold holds promise for a range of applications, unlocking the potential for sustainable fuel sources.

Fueling the Future:

- Diesel Production: Refined from the liquid output, pyrolysis fuel can be used as a sustainable substitute for traditional diesel.

- Gasoline Alternatives: The liquid hydrocarbons can undergo further refinement to produce gasoline-like fuels, contributing to the diversification of the fuel market.

- Aviation and Industrial Fuels: The high-energy content of pyrolysis fuel positions it as a contender for specialized applications, including aviation and industrial fuel needs.

Environmental Stewardship and Circular Economy:

Carbon Neutrality:

The beauty of the continuous pyrolysis machine lies in its potential to be a carbon-neutral solution. By converting plastics into fuel, it not only addresses the issue of plastic waste but also provides an alternative to fossil fuels, contributing to greenhouse gas reduction.

Closing the Loop:

- Resource Recovery: The process exemplifies resource recovery, turning what was once considered waste into valuable commodities.

- Circular Economy Principles: Embracing circular economy principles, plastic pyrolysis aligns with a sustainable approach where materials are reused and repurposed.

Challenges and Future Innovations:

Contending with Impurities:

The refining of pyrolysis fuel often contends with impurities that need to be meticulously addressed. Ongoing innovations focus on improving refining processes to enhance the purity and quality of the fuel.

Technological Advancements:

- Automation and Control Systems: Innovations in automation and control systems aim to optimize the pyrolysis process, ensuring precision and efficiency.

- Advanced Catalysts: The quest for superior catalysts continues, with researchers exploring materials that enhance selectivity and durability, pushing the boundaries of pyrolytic efficiency. As a professional manufacturer of pyrolysis equipment, Beston Group China provides you with the most cutting-edge plastic pyrolysis technology.

The Path Forward: Toward a Greener Tomorrow

In conclusion, the plastic pyrolysis machine emerges as a technological beacon, guiding us toward a greener and more sustainable future. Beyond waste reduction, it pioneers the conversion of plastics into a valuable resource – fuel. As the alchemy of pyrolysis unfolds within these machines, it beckons industries and environmental stewards alike to embrace the transformative power of technology in fostering a circular economy. The journey from plastics to fuel is not just a technological marvel; it is a testament to our ability to redefine waste, reduce our environmental footprint, and fuel a future where sustainability reigns supreme.