Establishing an egg tray production project requires a detailed understanding of the industry, proper planning, and the right resources. Egg trays are essential in the poultry industry for the safe transport and storage of eggs. This article outlines the critical steps to set up an egg tray production project, covering everything from sourcing an egg tray machine to understanding market dynamics.

Market Research and Feasibility Analysis

Before diving into the technical aspects, conducting thorough market research is essential. This involves analyzing demand for egg trays in your target region, understanding the competition, and identifying potential customers, including poultry farms and wholesalers. Additionally, a feasibility study should be conducted to assess the project’s financial viability, including initial investment, operating costs, and potential profit margins.

Selecting the Right Egg Tray Machine

Choosing the appropriate egg tray maker is a crucial decision that can impact the efficiency and quality of your production. There are several factors to consider when selecting an egg tray machine:

Production Capacity

The production capacity of an egg tray machine is measured by the number of trays it can produce per hour. This capacity should align with your projected production volume based on market demand. Machines with higher capacities are typically more expensive but can offer better economies of scale.

Automation Level

Egg tray machines come in different levels of automation, including manual, semi-automatic, and fully automatic. Fully automatic machines require less human intervention, which can reduce labor costs and increase efficiency. However, they also come with a higher price tag. The choice of automation level should be based on your budget, available workforce, and desired production efficiency.

Material and Energy Efficiency

Efficiency is critical in ensuring cost-effective production. Consider egg tray machines that are energy-efficient and capable of processing a variety of raw materials, including recycled paper and agricultural waste. Machines with advanced drying systems can also reduce energy consumption and improve the overall sustainability of your production process.

Supplier Selection

Identifying reliable egg tray machine suppliers is vital to securing a quality machine at a competitive price. When evaluating suppliers, consider their reputation, customer reviews, and after-sales support. It’s also important to compare egg tray machine prices from different suppliers to ensure you get the best deal without compromising on quality.

Understanding Egg Tray Machine Price Dynamics

Egg tray machine prices vary significantly based on factors such as production capacity, automation level, brand, and included features. Here’s a breakdown of the price dynamics:

Production Capacity

Machines with higher production capacities typically command higher prices. For example, a machine capable of producing 1,000 trays per hour will cost less than one that produces 5,000 trays per hour. However, the initial investment in a higher-capacity machine may be justified by the increased production volume and potential for greater revenue.

Automation Level

As mentioned earlier, the level of automation directly influences the price. Fully automatic machines are the most expensive, followed by semi-automatic, and then manual machines. The cost of automation should be weighed against the benefits of reduced labor costs and increased production efficiency.

Brand and Supplier

Well-known brands and reputable suppliers often charge premium prices due to their established reputation and quality assurance. However, investing in a reliable machine from a reputable supplier can reduce the risk of frequent breakdowns and costly repairs, ultimately saving money in the long run.

Additional Features

Some egg tray machines come with additional features, such as integrated drying systems, advanced control panels, and the ability to produce different types of trays (e.g., fruit trays, industrial packaging). These features can increase the egg tray machine price but may also add value to your production process by increasing versatility and reducing operational costs.

Setting Up the Production Facility

Once you have selected the appropriate egg tray machine, the next step is to set up the production facility. The facility should be designed to accommodate the entire production process, from raw material storage to finished product packaging.

Location Selection

The location of your production facility should be strategically chosen based on proximity to raw material sources, access to transportation networks, and availability of labor. Additionally, ensure that the facility is compliant with local zoning laws and environmental regulations.

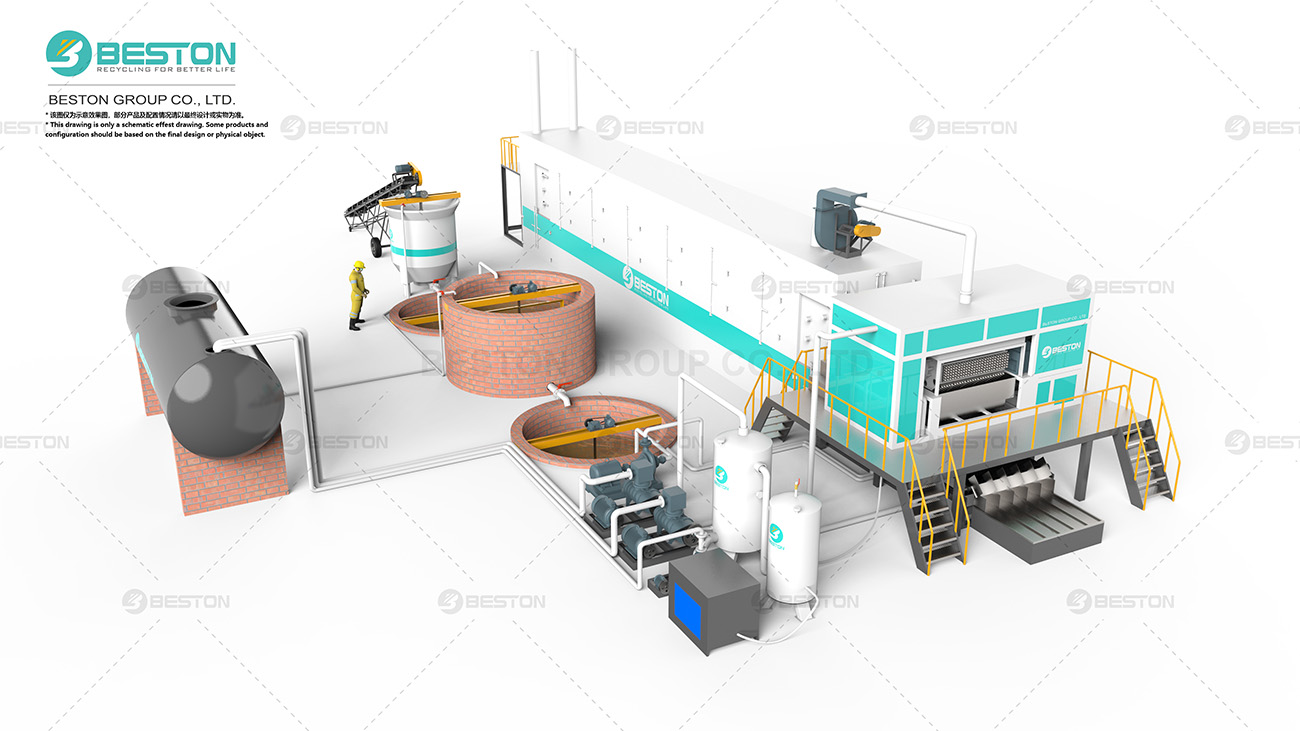

Layout and Infrastructure

The layout of the production facility should facilitate a smooth workflow, with designated areas for raw material storage, production, drying, and packaging. Adequate infrastructure, including water supply, electricity, and waste management systems, is essential for efficient operations. The drying area, in particular, requires careful planning, as it is one of the most energy-intensive parts of the production process.

Staffing and Training

Your production facility will require a skilled workforce to operate the egg tray machine and manage the production process. Depending on the level of automation, the number of staff needed may vary. Ensure that your staff receives adequate training on machine operation, safety protocols, and quality control procedures to minimize downtime and ensure consistent product quality.

Raw Material Procurement and Management

The primary raw material for egg tray production is waste paper, which can be sourced from recycling centers, paper mills, or other industrial sources. Establishing a steady supply chain for raw materials is critical to avoiding production delays.

Raw Material Quality

The quality of the raw material directly impacts the strength and durability of the final product. It’s important to source high-quality waste paper and to have a quality control process in place to ensure that only suitable materials are used in production.

Inventory Management

Efficient inventory management is crucial for maintaining a consistent production schedule. Implementing a just-in-time inventory system can help reduce storage costs and minimize waste. Additionally, ensure that your facility has adequate storage space to accommodate raw materials and finished products.

Production Process Overview

The pulp moulding machine working process involves several key steps, from pulping to drying:

Pulping

Raw materials are first pulped using water and mechanical agitation to create a slurry. This slurry is then refined to achieve the desired consistency for forming the egg trays.

Molding

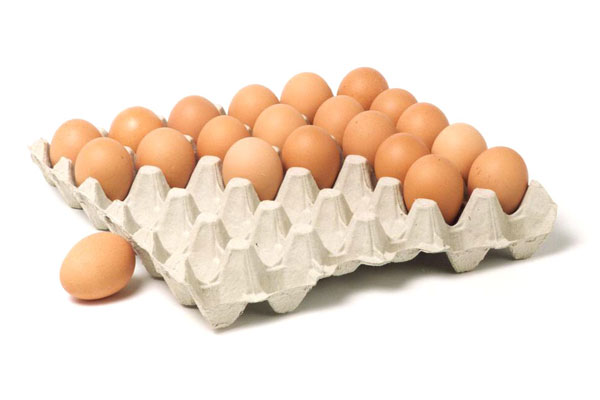

The slurry is transferred to molds where it is shaped into egg trays. The molds are designed to create trays with specific dimensions and configurations based on customer requirements.

Drying

Once molded, the trays need to be dried to remove excess moisture. This can be done using natural drying methods or mechanical dryers, depending on the available infrastructure and climate conditions.

Packaging

After drying, the trays are inspected for quality, stacked, and packaged for transport. Proper packaging is essential to prevent damage during shipping and ensure that the trays reach customers in good condition.

Marketing and Distribution

With production underway, the final step is to market and distribute your egg trays. Developing a strong brand identity and establishing relationships with poultry farms, wholesalers, and retailers will be key to your success.

Market Positioning

Position your egg trays as a high-quality, cost-effective solution for customers. Highlight the benefits of your trays, such as durability, environmental sustainability, and competitive pricing.

Distribution Channels

Establish distribution channels that allow you to reach your target customers efficiently. This may include direct sales to poultry farms, partnerships with wholesalers, or online sales platforms. Consider offering flexible order quantities and delivery options to attract a broader customer base.

Conclusion

Setting up an egg tray production project requires careful planning, strategic decision-making, and a thorough understanding of the industry. By selecting the right egg tray machine, managing raw materials effectively, and positioning your product in the market, you can establish a successful and sustainable business. As the demand for environmentally friendly packaging solutions continues to grow, investing in egg tray production offers both economic and ecological benefits.