Pyrolysis plants stand as a beacon of hope amidst the escalating concerns of environmental degradation, offering multifaceted benefits that extend far beyond waste management.

Mitigating Air Pollution: A Key Advantage of Pyrolysis Technology

At the heart of the pyrolysis plant lies a sophisticated mechanism designed to transform various types of waste into valuable resources while curtailing detrimental environmental repercussions. One of the paramount advantages of pyrolysis plants resides in their capacity to mitigate air pollution.

Alleviating Strain on Landfill Sites: A Sustainable Waste Management Solution

Moreover, pyrolysis plants significantly alleviate the strain on landfill sites, offering a viable alternative to conventional waste disposal methods. By diverting organic waste from landfills, these facilities not only minimize the risk of soil and groundwater contamination but also mitigate the generation of methane, a potent greenhouse gas.

Resource Conservation: Recovering Value from Waste Streams

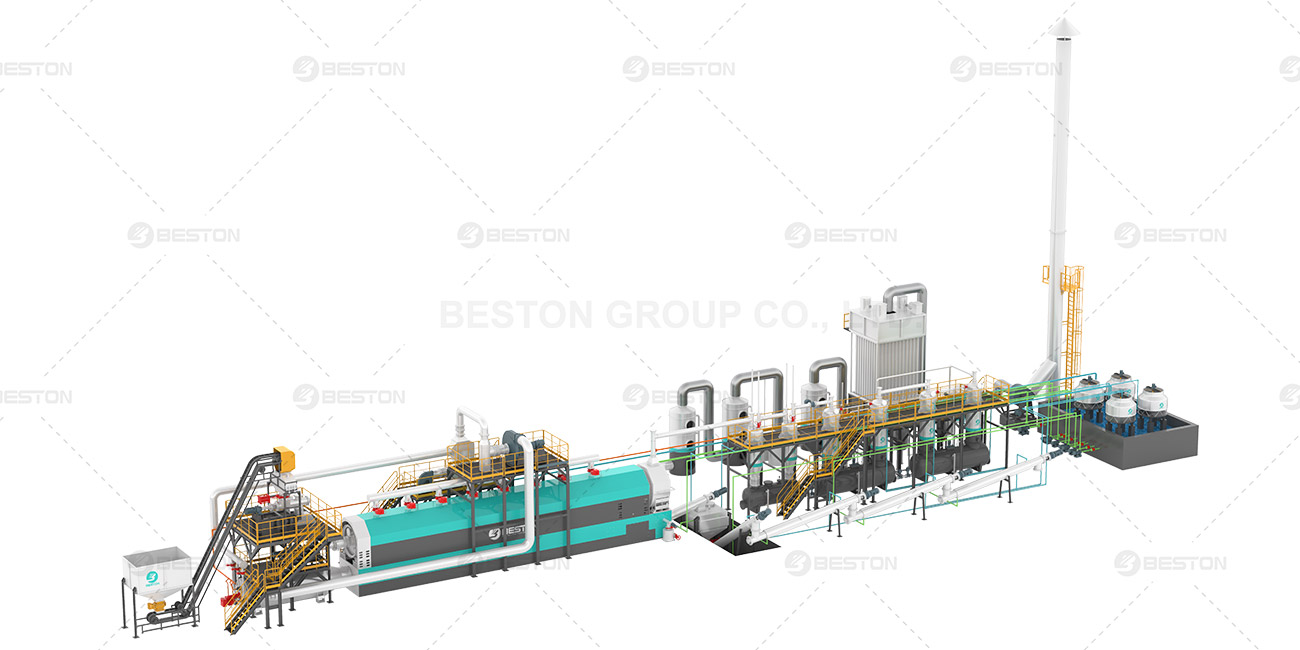

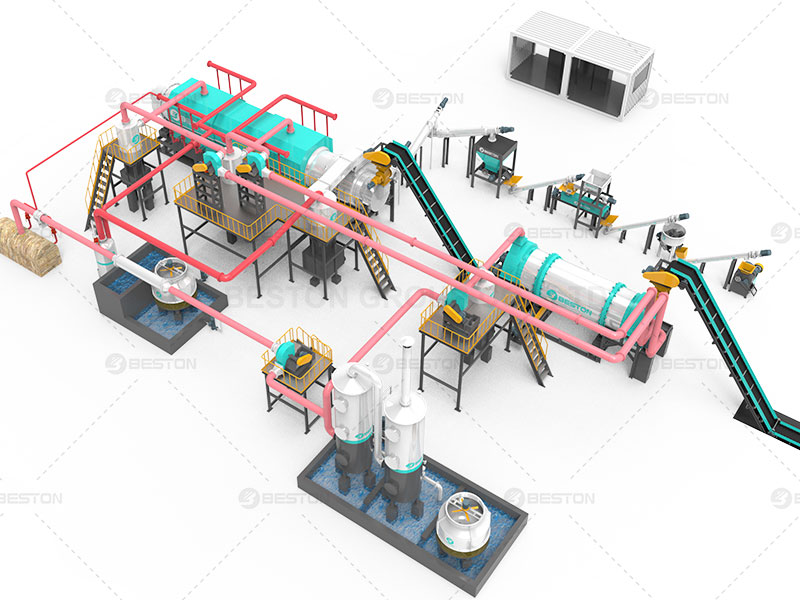

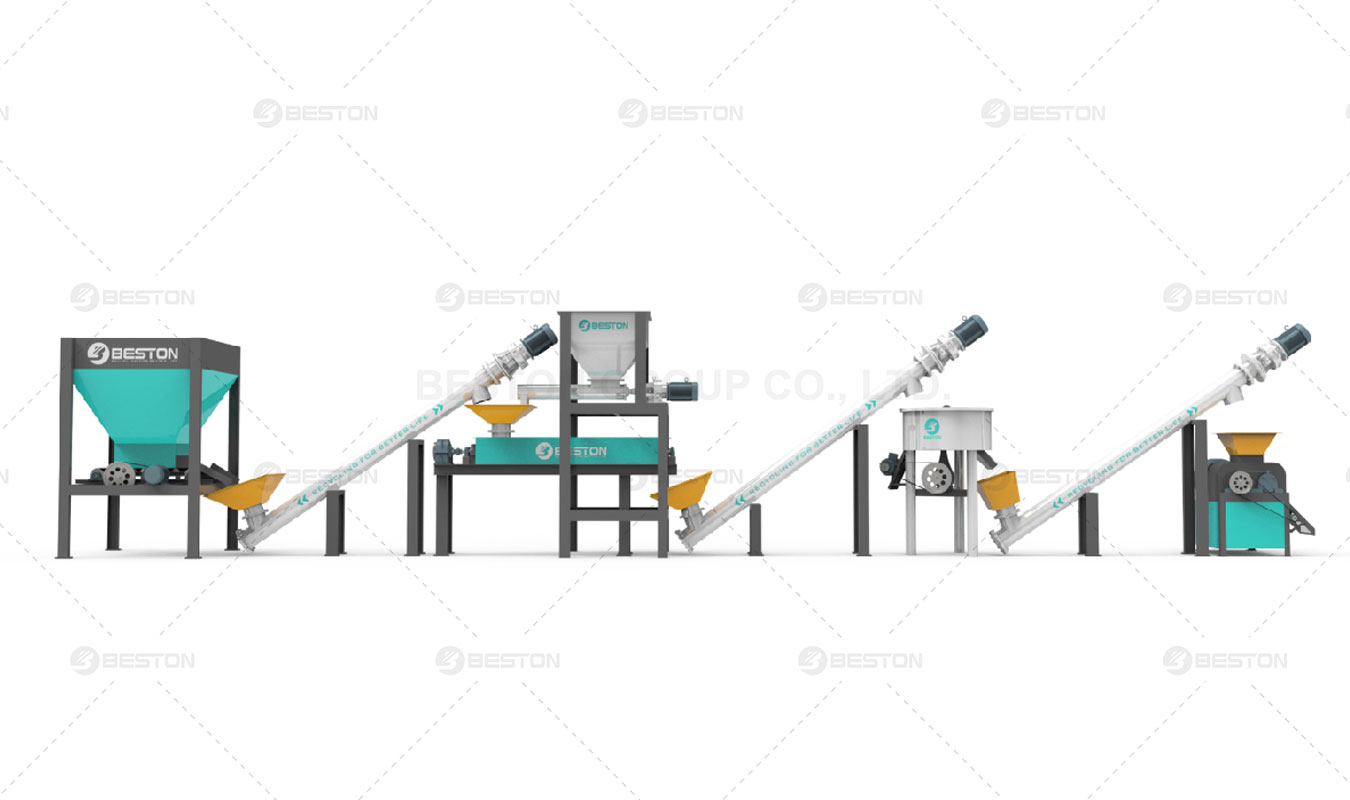

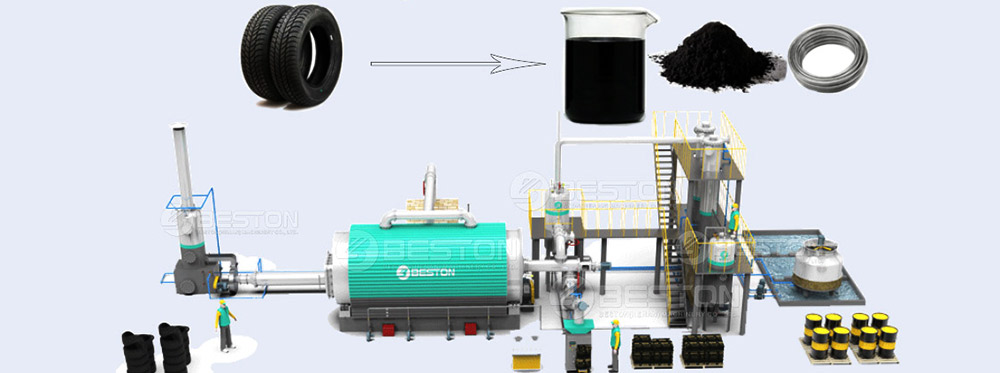

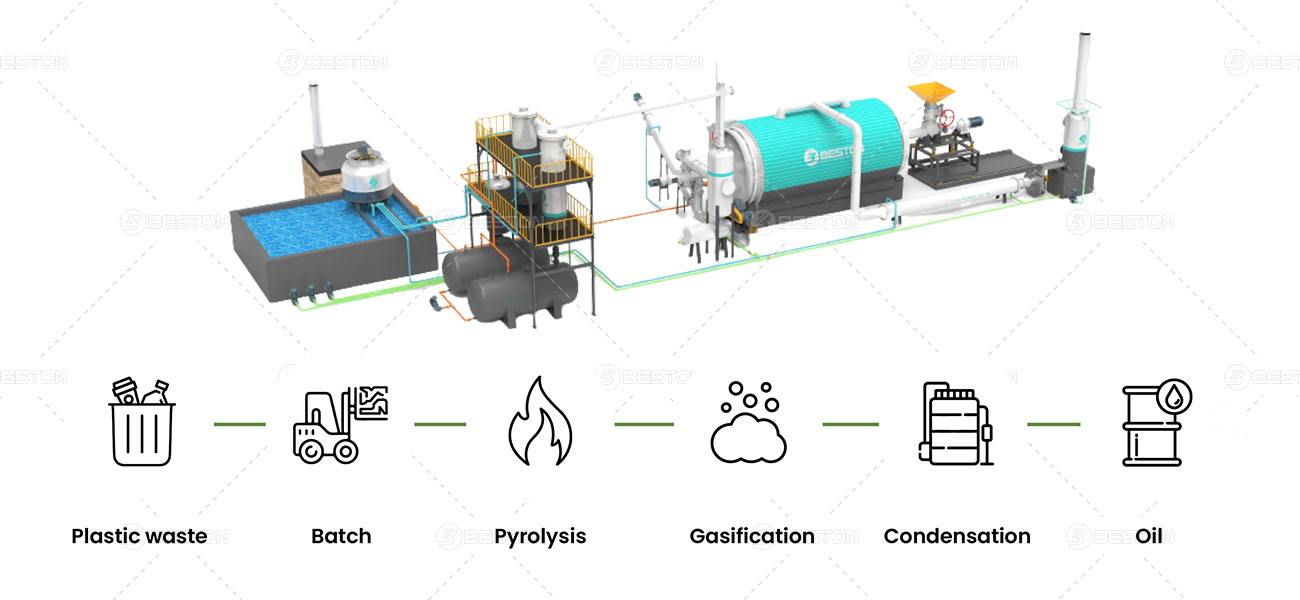

Furthermore, pyrolysis plants play a pivotal role in resource conservation by facilitating the recovery of valuable materials embedded within waste streams. Through the process of thermal decomposition, pyrolysis yields a spectrum of secondary products, including biochar, syngas, and bio-oil, which can be harnessed for energy generation or utilized as raw materials in various industrial processes.

Combating Plastic Pollution: A Sustainable Solution

In addition to curbing environmental degradation, plastic pyrolysis machine present a viable solution to the burgeoning crisis of plastic pollution. By converting discarded plastics into reusable fuels and chemicals, these facilities mitigate the proliferation of plastic waste in oceans and landfills, thereby safeguarding delicate ecosystems and marine biodiversity.

Advancements in Pyrolysis Technology: Enhancing Efficiency and Sustainability

The advent of advanced pyrolysis technologies, such as microwave and plasma pyrolysis, holds promise in enhancing the efficiency and sustainability of pyrolysis plants. By optimizing plastic/tyre pyrolysis process parameters and enhancing heat transfer mechanisms, these innovations pave the way for higher yields and reduced energy consumption, further bolstering the environmental credentials of pyrolysis as a waste management solution.

Integration into Waste Management Infrastructures: A Strategic Pathway to Global Sustainability

Moreover, the integration of pyrolysis plants into existing waste management infrastructures offers a strategic pathway towards achieving global sustainability targets. By fostering collaboration between governments, industries, and communities, stakeholders can leverage the transformative potential of pyrolysis to transition towards a more circular and resource-efficient economy.

In conclusion, batch/continuous pyrolysis plant represent a paradigm shift in waste management practices, offering a sustainable solution to the pressing environmental challenges of our time. Through their capacity to mitigate air pollution, conserve resources, and combat plastic pollution, these facilities exemplify the convergence of innovation and environmental stewardship. As we stand at the precipice of a defining moment in human history, pyrolysis plants emerge as beacons of hope, illuminating the path towards a greener and more sustainable future.