Are you interested in purchasing small scale pyrolysis equipment? If you’re considering equipment like this, you’ll want to make sure you have the complete picture. You’ll want to take both the advantages and drawbacks into account and use that information about small pyrolysis plant to make a decision that you can live with.

Your Plant Can Produce Many Different Products

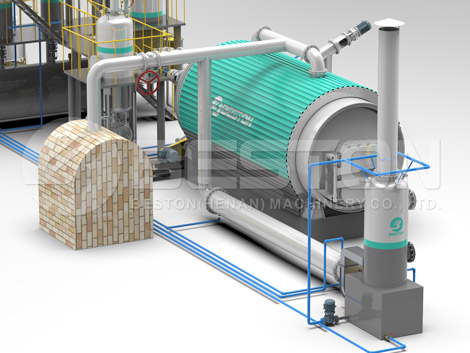

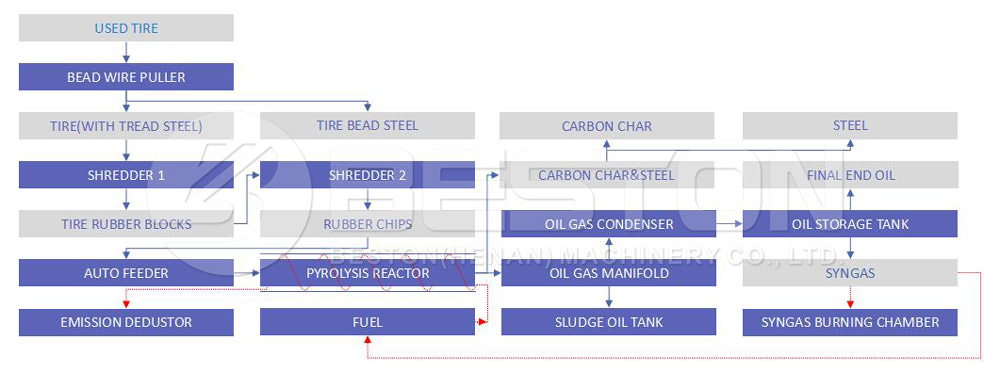

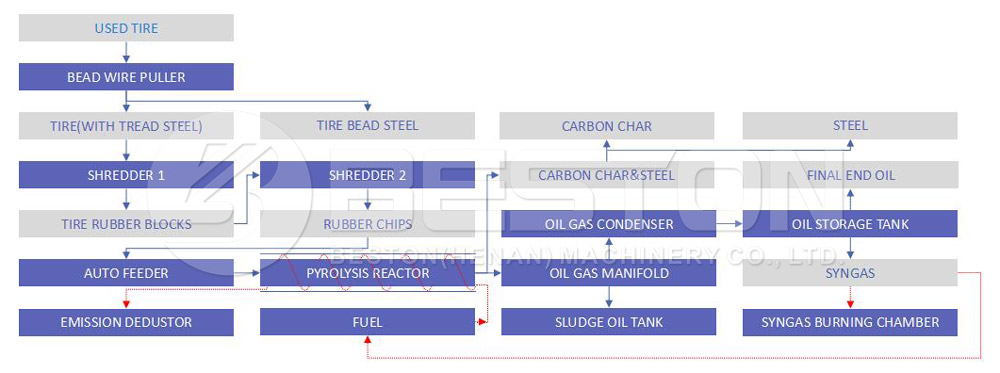

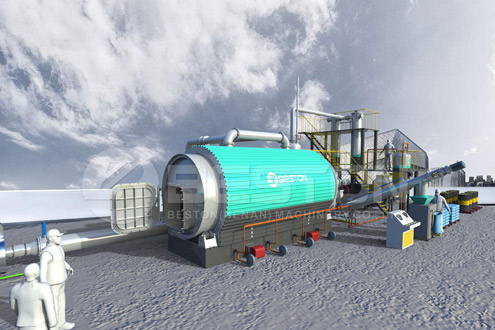

There are three main products that can be produced with pyrolysis equipment: oil, steel wire, and carbon black. It is possible to produce all of these products with a small scale plant, but you will be limited in the number of products that you can produce.

You’ll be able to achieve a number of things with your plant. Once you invest in the pyrolysis machine, you’ll be able to start producing valuable products, and you’ll be able to use these products in a way that you deem to be efficient.

It’s An Environmentally Friendly Solution

Although pyrolysis plants are able to recycle waste materials, they can still take a toll on the environment because they typically consume a great deal of power. If you choose to invest in a small scale plant, however, you’ll be able to reduce the amount of energy that you consume.

Not only can a small scale plant save you money, but it’s also an eco-friendly alternative to a larger plant. If you want to explore pyrolysis technology, and you’ve been searching for ways to reduce your carbon footprint, investing in this equipment could be a very wise choice.

You Can Get A Lot For Your Money

When you invest in equipment like this, you’ll be able to do a great deal, even if your budget is fairly limited. There are many excellent options available, and a lot of the machinery that you see will be reasonably priced.

Cost is a major consideration for many people that choose to invest in equipment. Thankfully, if this is a concern for you, you’re likely to find many reasonable options within your price range. In many cases, choosing to buy small-scale equipment will allow you to enjoy significant savings. It can manage various raw materials: https://bestonasia.com/oil-sludge-pyrolysis-plant/.

There Are Many Options To Choose From

The cost of the technology necessary to produce small scale equipment like this has lowered, and the demand for both pyrolysis equipment and small scale machinery has risen. Due to these factors, it’s likely that there will be a large selection of products available to you.

Having more options means it will be easier for you to find a solution that meets your needs and is in line with your budget. It means you won’t have to make significant sacrifices. You’ll be able to work with a dependable supplier and invest in the type of equipment that you want.

If you weigh the pros against the cons, you’re likely to find small scale pyrolysis equipment to be a smart investment from Beston Company. When you buy small scale equipment, you’ll be able to enjoy many advantages, and you’ll also be able to do a lot even with a smaller budget.