Americans wear out millions of pounds of rubber tires every few weeks. The rubber that wears off these tires is enough to make millions of new tires. According to the EPA, reclaimed rubber is responsible for creating about 290 million so-called scrap tires. Reusing this material is one way to save resources and protect the environment. How is tire waste reclaimed? Through waste tyre pyrolysis plant.

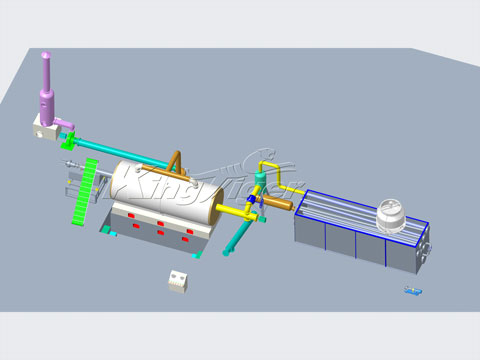

Process Explained in Detail

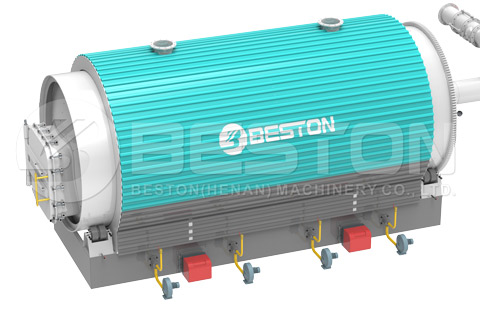

Pyrolysis is a method that recycles used tires by heating the existing rubber as a whole or in shreds. This process is done in an oxygen-free reactor vessel. The heating process breaks down the rubber into small molecules. According to the online source, it will need new tires every few years. The pyrolysis method assures them of getting these new tires using old rubber thereby conserving the material and putting it back into use.

Most rubber is made from petroleum and this is considered a toxic substance. Using the pyrolysis method allows new products to be made without the use of more petroleum. Not only does this protect humans but it also protects wildlife and the environment.

Once the pyrolysis plant is filled with the existing rubber products that are heated down then the reactor of the plant will soften the polymers contained in them. When these are broken down into small molecules they can then be reconstituted into things like fuel oil.

This is one of the best byproducts of pyrolysis. This fuel can be carried in tanker trucks to new destinations for use. Another product that is created by the process is carbon black.

This product can be used as a main or raw ingredient in the manufacturing of many other products. It has a strengthening property that allows it to be part of new products that are made with more durability and efficiency. It is an overall good economic product to create from recycled tires because of how long it lasts and because of the numerous new products that it can make. Products that can be made from this material include cables, nylon bags, and doormats.

During the tyre pyrolysis plant project report, it seems that this process is cost-effective. It can be implemented relatively quickly and can go towards recycling tires and creating these new fuels and other products.

A tire pyrolysis plant would need to be established in an area where this recycling process is to occur. Many states including Maryland have imposed tire fees on the purchase of tires. These fees go towards paying for the plant and the process.

For now, the fees look like they will go towards building facilities where the plants can be installed. The pyrolysis machines are sold by industrial manufacturers around the world. Contracts must be drafted between municipalities and the manufacturers according to the results of the reports done. Tire pyrolysis is a very promising solid waste recycling plant emerging today.