A pulp molding machine is the type of equipment designed to recycle waste paper such as cardboard and newspapers into egg cartons, egg trays, fruit trays, seedling trays, cup holders, shoe boxes and so much more.

Reasons To Invest In A Paper Molding Machine

Great ROI

When considering the smallest of the pulp molding machines, this equipment is capable of making 1,000 trays every hour While the fully-automated models can produce 6,000 trays every hour. The manual egg tray machines are highly productive and they use waste paper as the raw material (which is very easy and cheap to get). This is why pulp molding production lines are an excellent investment.

Very Low Failure Rate

When purchasing a pulp molding machine from a reputable and well-established manufacturer, you can be sure that your equipment is going to last. These machines are also rotary, making them a lot safer to use and since the processes are automated it reduces the failure rates even further.

Simple Operation

As mentioned above, pulp molding machines are automated, which means they are very simple to operate. This also does away with having to employ skilled workers which also helps to keep pulp molding machine prices and other costs down.

Eco-Friendly Design

Pulp molding machines produce molded products such as trays from biodegradable materials. With the increasing concerns surrounding plastic, paper trays have increased in popularity. More importantly, the production line of pulp molding is virtually pollution-free.

Wide Applications

Since manufacturers are able to customize the molding dies, it makes it easy to invest in the tray types you are going to need. You can also choose to change out the dies to increase the product range you plan to sell.

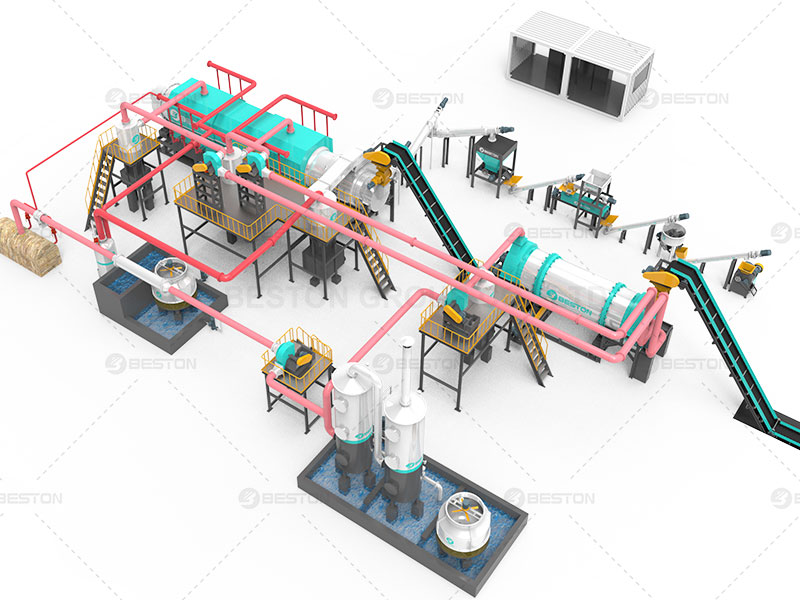

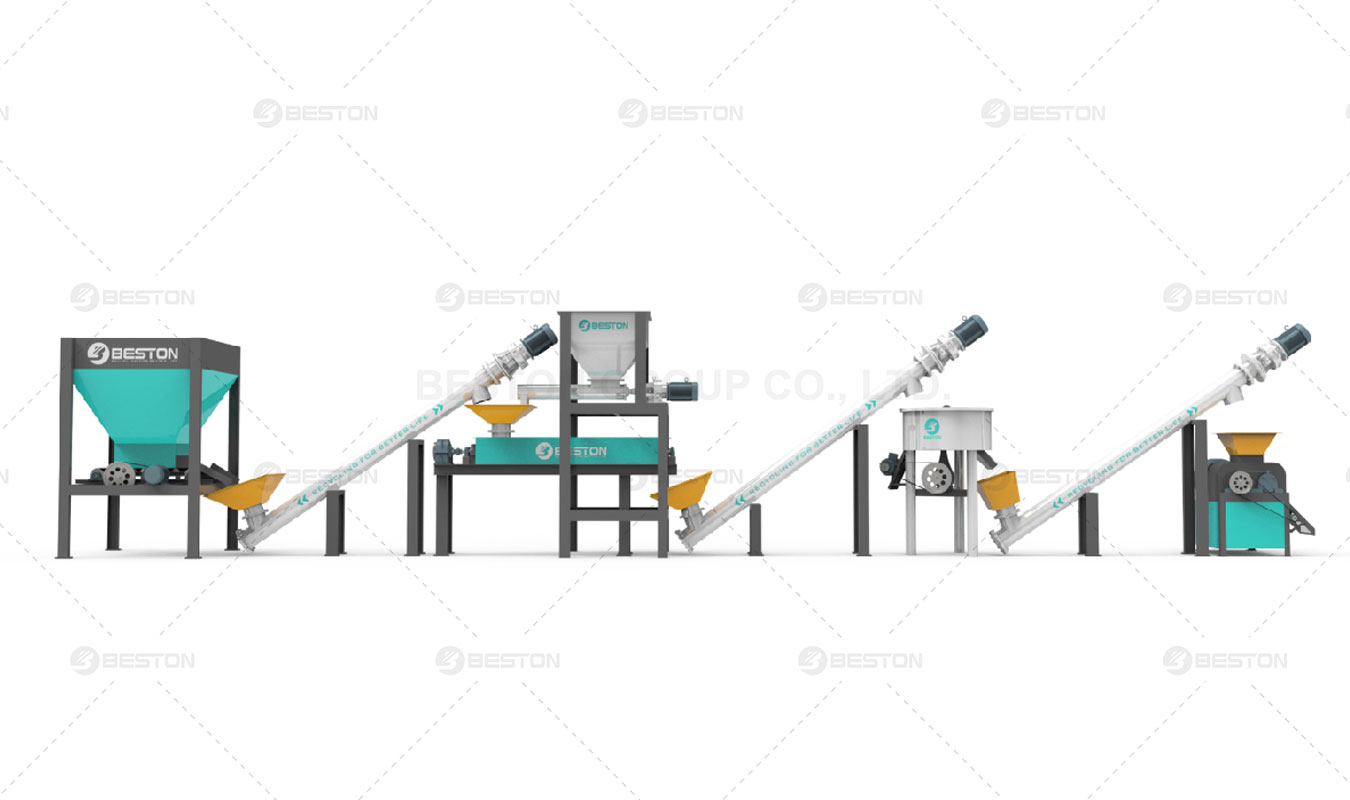

The Pulp Molding Process

The molded pulp packaging machinery plays an important part in the entire system. The combination of a cleaning device, air compressor, and vacuum pump, is what contributes to an entirely automatic process. The process begins by pulping the paper into a pulp before it is sent to the forming molds. From here the pulp will be pressed tightly into the forming mold using the vacuum pump. During these processes, most of the water will be removed from the molds. The next step of the process involves the air compressor which demolds the wet trays. The last step of the process involves drying the trays.

How To Choose The Right Pulp Molding Machine

The first step of the process is to ask yourself these questions:

What Do You Plan To Use The Trays For?

Examples of this include fruit trays, egg cartons, or egg trays. This will determine what type of molding dies you are going to need.

How Many Trays Do You Need To Make Per Hour?

The industrial packaging machine models can produce anything from 1,000 to 6,000 trays every hour.

How Much Do You Plan To Spend On This Business?

Keep in mind that the pulp molding machine only contributes to a portion of the costs involved. You will also need to consider other costs involved such as space, construction, maintenance, and labor.