Buying the right machinery is a good investment because it can give you a lot of benefits. It is important to put time and effort into the process so you end up with the right option. There is no need to hurry the process the regret it when you end up with something you don’t like. Investing in the right equipment is going to pay you back many times over. If you want to make egg trays, you don’t have to spend a lot of money getting a big machine. There are smaller options that won’t cost you much. You will be able to meet your production goals without breaking the bank.

A small egg tray machine is going to serve you well and you will be happy with this purchase. There are many benefits you can expect to get from this machine. Below are some of the benefits you are going to see.

Cost-effective

It is cost-effective to buy a small egg tray machine when compared to other types of manufacturing equipment. If you are getting started with making egg crates, you don’t need to spend a lot. This means you don’t have to expose yourself to a lot of risks. There is a wide range of options to choose from, which means you have a good chance of finding something that works for you. Talk to professionals and you will have the machine in no time. You can then buy a bigger one when you need to produce more. You will be surprised at how cheap is the paper egg tray making machine price.

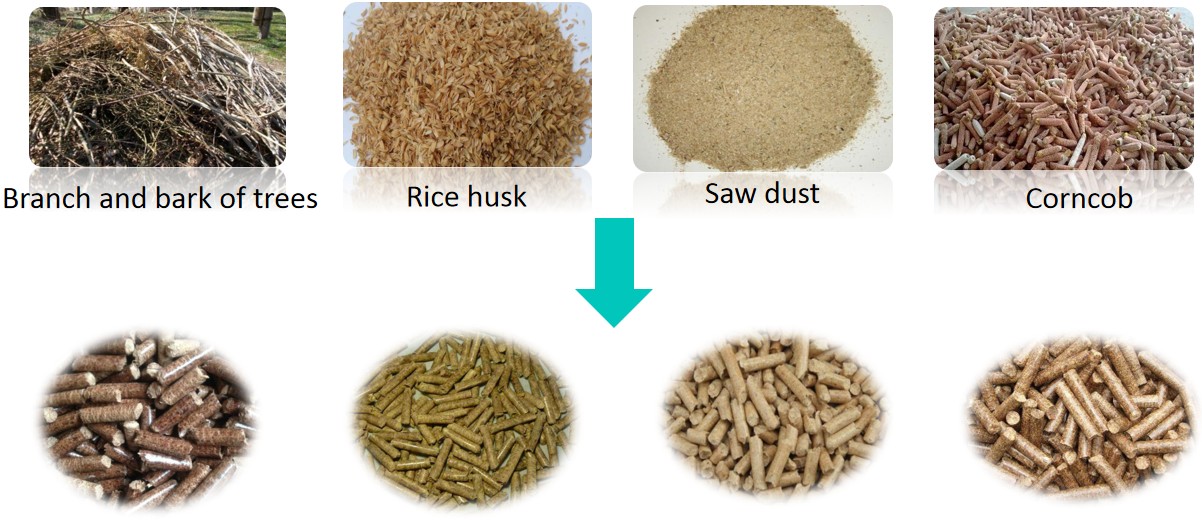

Cheap raw materials

Making egg trays is not that expensive because the raw materials used are quite affordable. You can make them from recycled materials that you can gather free of charge. You can avoid spending money on raw materials. This increases your profit margins. Your work will be to find a flow of recyclable paper, which can easily find.

Good for the Environment

Since the egg trays are made from recycled materials, you will be doing something positive for the environment. When the egg trays have been used many times, they can be recycled into new egg trays again. This doesn’t result in extra waste. If you care about the environment, consider investing in a small egg tray machine. Beston machines have been successfully installed in many places: https://pulpmouldingmachines.com/egg-tray-making-machine-in-india/.

Easy to Operate

It is easy to operate a small egg tray machine. You don’t have to hire many people to operate the machine. The process of making trays is simple and you don’t need specialized training. With time, you will improve your efficiency and get more from the machine. It is not complicated to operate a small egg tray machine.

There are many other benefits you are going to get when you buy an egg tray machine. There are many options and you will most likely find something that works for you. Take your time and look at the different options before choosing the best pulp moulding machine manufacturers. This is a great investment that you need to make and get all the benefits above and more.