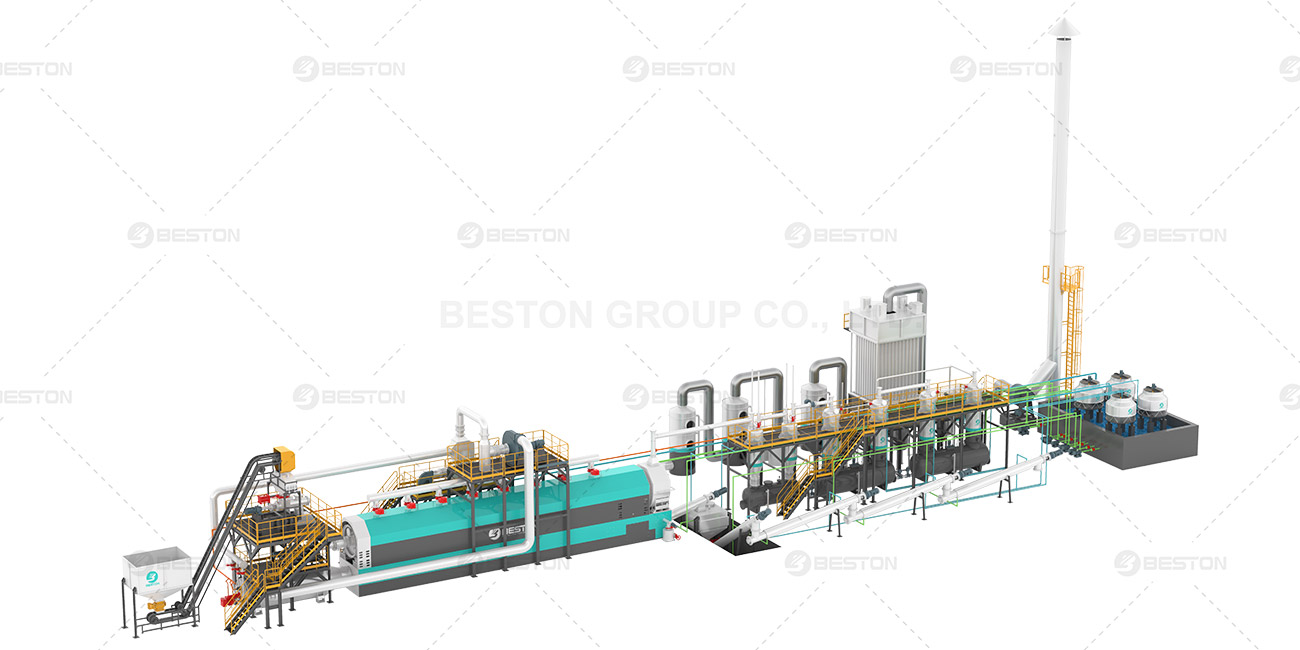

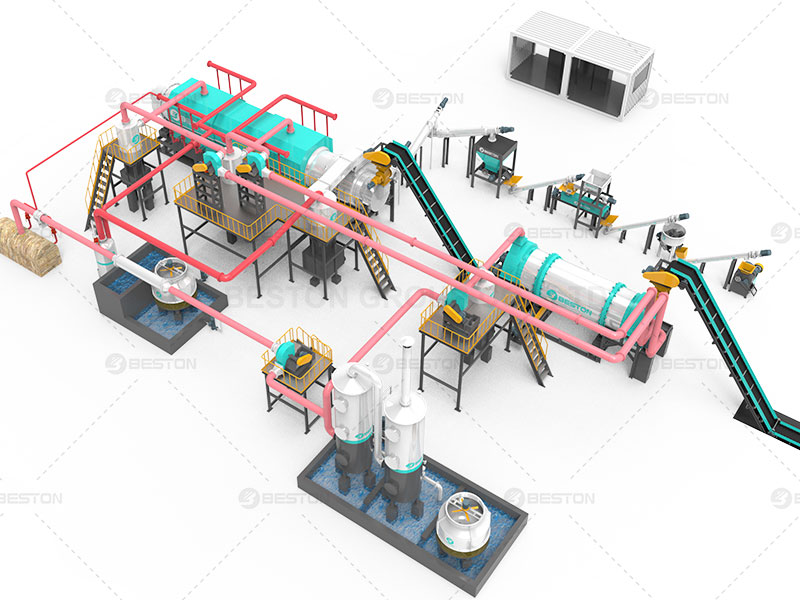

In our quest for sustainable and environmentally friendly solutions, tyre recycling pyrolysis plants have emerged as a game-changer in waste management. These innovative machines offer a unique approach to tackle waste-related challenges by transforming various types of waste into valuable resources through the process of pyrolysis. Let’s delve into the compelling reasons why you should consider embracing tyre recycling pyrolysis plant.

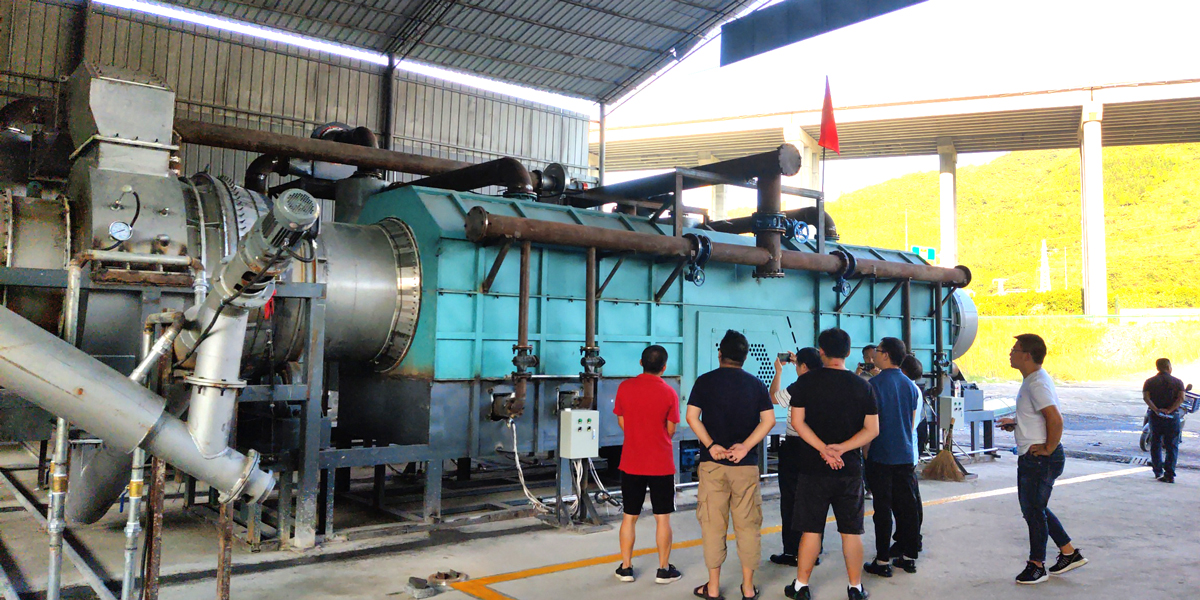

Waste Diversion: Recycling pyrolysis plants provide an effective method to divert waste from landfills and incineration. Instead of disposing of waste materials, these plants utilize the pyrolysis process to thermally decompose them in the absence of oxygen. This process converts the waste into useful end-products such as fuel oil, carbon black, and combustible gas. By diverting waste from traditional disposal methods, recycling pyrolysis plants contribute to waste reduction and promote a more sustainable waste management approach.

Energy Generation: Recycling pyrolysis plants also play a vital role in sustainable energy generation. The pyrolysis process generates combustible gases that can be captured and utilized as an energy source. These gases can fuel the pyrolysis process itself, reducing the need for external energy inputs. Additionally, the excess energy produced can be used for electricity generation or other industrial applications. By harnessing the energy potential of waste, recycling pyrolysis plants contribute to reducing reliance on fossil fuels and promoting renewable energy alternatives.

Environmental Benefits: Embracing continuous waste tire pyrolysis plant offers significant environmental benefits. By diverting waste from landfills and incineration, these plants help mitigate the environmental impacts associated with waste disposal. The pyrolysis process itself has lower emissions compared to traditional waste management methods, contributing to air pollution reduction and a healthier environment. Additionally, the extraction and utilization of valuable resources from waste materials help conserve natural resources and minimize the need for virgin materials.

Economic Opportunities: Investing in recycling pyrolysis plants can create economic opportunities and contribute to local economies. By establishing a recycling business focused on pyrolysis, you can generate revenue from the sale of the end-products, such as fuel oil and carbon black. These products have various industrial applications and can be sold as valuable commodities. Moreover, the recycling industry has the potential to create employment opportunities, supporting local communities and contributing to sustainable economic growth.

Waste Management Innovation: Embracing recycling pyrolysis plants signifies a commitment to waste management innovation. These plants offer a technologically advanced solution to address waste challenges, providing an alternative to traditional waste disposal methods. By adopting these innovative machines, you contribute to pushing the boundaries of waste management practices, promoting sustainability, and encouraging further advancements in the field.

In conclusion, embracing recycling pyrolysis plants brings a multitude of benefits, including waste diversion, resource recovery, energy generation, environmental advantages, economic opportunities, and fostering waste management innovation. By investing in these plants, you play a crucial role in promoting sustainable waste management practices and contributing to a more circular and resource-efficient economy. Join the movement towards a greener future by embracing recycling pyrolysis plants and making a positive impact on the environment and society. If you are looking for a manufacturer, take a view at this page: https://www.bestongroup.com/zh-CN/.