The wood charcoal making machine allows charcoal to be produced from wood. This occurs during the biomass pyrolysis process. If you didn’t already know, wood charcoal contains a great deal of carbon that can be used as an absorbing element. Let’s dive into the wood charcoal making machine.

This particular industry is now a booming market. However, creating charcoal in this form has always been a popular move. With that said, charcoal kilns weren’t always a friendly source. As a result, you’re going to need a new state-of-the-art plant from a leading manufacturer.

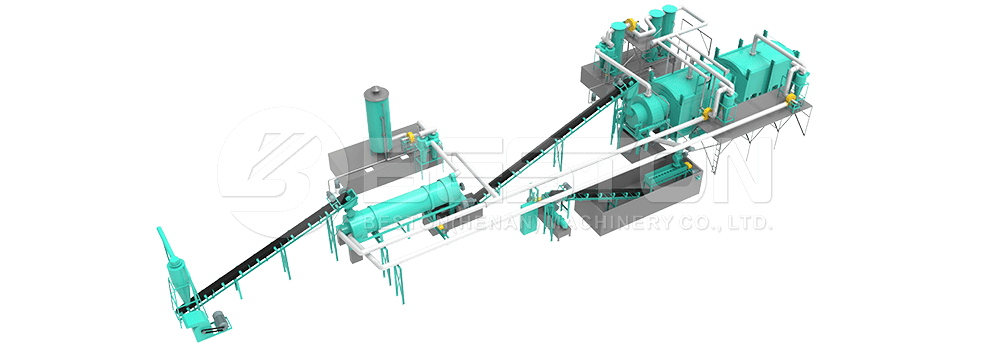

Within the lineup, there are several variants of the charcoal making machine. They were simply built to hold different capacities of material during processing. The plants are also known for being able to process bamboo, sawdust, palm and coconut shells, industrial sludge, civil and municipal sludge.

After processing, the charcoal be used in several ways, This even includes fuel and that in itself is essential for cooking and creating warmth. Additionally, there are also some industrial advantages that offer a higher caloric value. This is very useful since pollution is reduced.

The charcoal produced is so porous that it easily absorbs both gases and liquids on its surface. This means that it can be used as a filtering media. However, if you’re looking to create extra profits, this can be done by further processing the wood charcoal to create activated carbon. Activated carbon usually goes for a higher price on the markets. In addition to the wood charcoal making machine, the coconut shell charcoal making machine is also very popular because coconut shell charcoal is a great raw material for activated carbon.

Besides the main byproduct charcoal, wood vinegar and tar are also produced. They as well also have their own desired set of applications. Tar is important and is used for dealing with corrosion. Wood vinegar is used in the food and medicinal industries.

Since the process is exothermic, combustible gas is produced. Wood vinegar is also produced from the plant and provides another income stream for potential investors. However, before the process can begin there are several things that must be done.

The biochar production process is simply a spontaneous breakdown while increasing carbon in a depleted oxygen environment. Harmful contents and smoke are quite volatilized during the reaction. However, this ensures that the finished product is tasteless and smokeless.

Before the process can occur, the raw materials must be pre-treated. The water content should be less than or equal to 15% and the diameter should be no more than 15mm. When these parameters are introduced at the beginning they create a better end product. The pretreatment phase also ensures that costs are driven down since fuel doesn’t need to be externally sourced.

The carbonization furnace is then preheated for an hour to improve the working efficiency of the machine. Charcoal is usually discharged after 20 minutes have passed. At the 30 minute mark, combustible gasses are produced and recycled. After being produced, the charcoal is then discharged.

The machine also comes equipped with a dedusting system. This ensures that produced or rather combustible gasses are processed. Various impurities are removed during this stage and it doesn’t produce a threat to the environment. More details can be found: https://wasterecyclingplant.com/biomass-pyrolysis-plant/.

As we conclude, we have just looked at the wood charcoal making machine. These machines benefit the environment and they generate another stream of income. So if you’re looking to invest, this might be the one for you.