For years lots of industrial, commercial, and agricultural waste has piled up in landfills by the millions of tons. It takes years for some of this waste to decompose back into usable products and by that time millions more tons have been deposited on top of it. There has been a recent push to make this waste more productive, easier to handle, and less expensive for producers to dispose of. This is where biochar comes in. It is very similar chemically to charcoal and activated charcoal, but has some differences that make it an important product in both agriculture and waste disposal, let’s take a look. Get high quality biochar equipment for sale before purchasing.

How Is Biochar Made And From What?

There are literally thousands of different organic wastes that can be turned into biochar. Everything from waste coconut shells to leftover restaurant food, and from straw to sewer sludge. Nearly everything that was once a growing plant, or part thereof, can be turned into biochar.

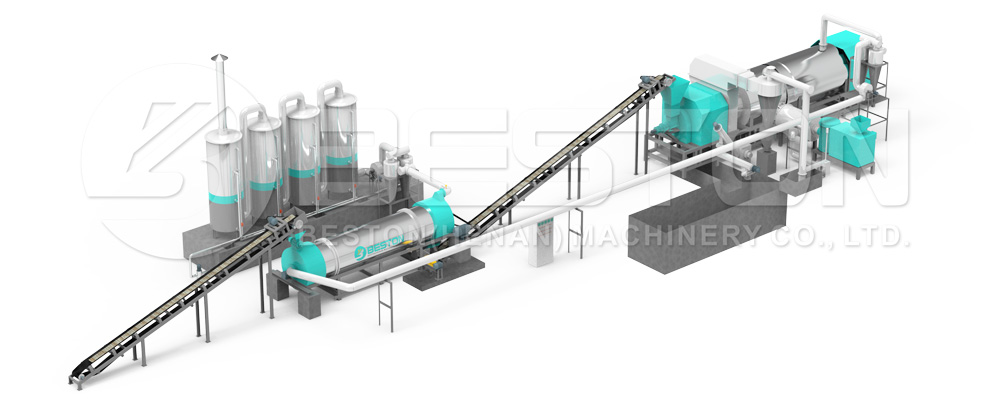

The actual biochar product is made by heating up the waste material in a non-oxygen environment. The temperature varies, but usually from 400 C to 700 C is needed to reduce the organic material down to simple ingredients like oils, gases, and carbon. There are now plenty of biochar equipment for sale that can handle the procedure. More information on coconut shell charcoal making machine here.

Biochar Can Be Used In Several Ways

The term biochar is sometimes used specifically to refer to a specific type of carbon. Other times it’s more generically used to refer to any of the charcoal products that are produced by the pyrolysis thermochemical process. In that case, the biochar can be of several different grades of carbon, some used as fuel, or to make charcoal briquettes.

Other grades are used in agriculture to condition soil and sometimes as actual fertilizer. There are also industrial processes that can use pure carbon black in the manufacturing of black rubber products like tires and plastics.

If Your Biomass Is Wet

You can look for specific biochar equipment for sale that has a pre-drying process as part of the charcoal making machine. It uses the waste gases as a combustible to heat up the biomass and pre-dry it before it enters the reaction chamber. This helps save on energy use since the gas comes directly from the process.

Many different kinds of biomass, specifically sewage sludge, restaurant waste, commercial agriculture waste, and others are wet on arrival. With the right processing plant, no time needs to be expended in the drying phase which quickens the entire process.

After The Process The Commodities Are Valuable

The waste products that come out of the pyrolysis plant are usually quite easy to sell. They are typically several different viscosities of oil, heavy, medium and light, each of which can either be used “as is” or refined into other products. The various products can be anything from lubricants to fuel oils.

Since there is no oxygen in the reaction chamber, the biomass isn’t allowed to burn. This keeps the exhaust gases clean and free of toxic chemicals and allows for the thermochemical decomposition of the biomass to be complete without any flames.

If you have a large amount of biomass on a continuing basis, you’re in the market for a wood charcoal making machine. They pay for themselves by reducing dump fees and also by the sellable byproducts they create.