Unraveling the Plastic Predicament

Plastic pollution has become an omnipresent specter, infiltrating every corner of our planet. The conventional methods of plastic disposal, such as landfilling and incineration, have proven to be ecologically disastrous, exacerbating the already critical climate crisis. Enter the plastic to oil machine—a technological alchemist aiming to transmute the environmental menace into a sustainable boon.

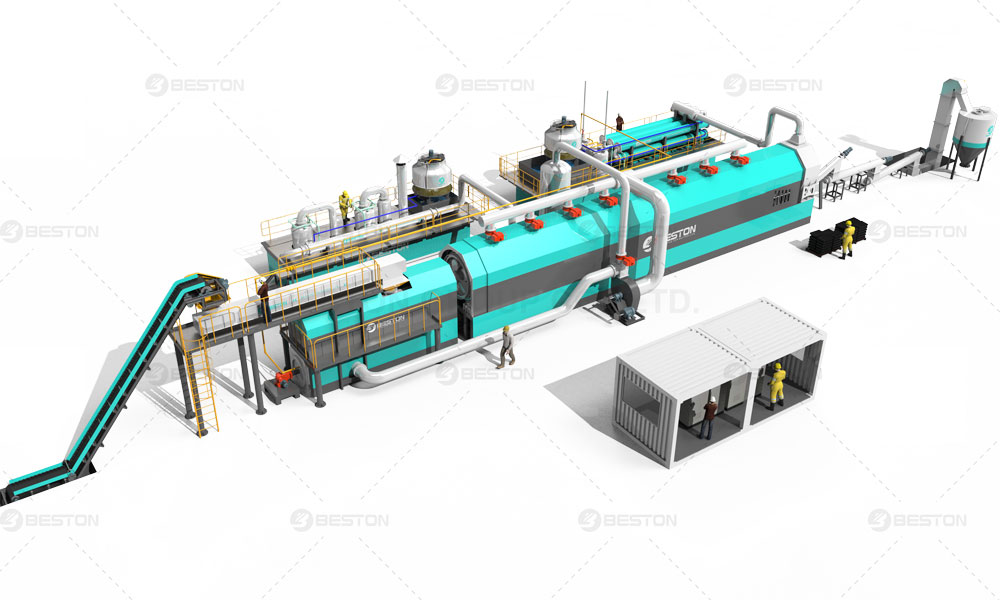

At the heart of this transformative process lies the intricate dance of plastic pyrolysis plant. In the controlled environment of a pyrolysis plant, plastics undergo a metamorphic journey. The high temperature and absence of oxygen coax the molecular structures of plastic to break down, yielding a spectrum of hydrocarbon products. The pinnacle of this transformation? Liquid gold in the form of synthetic oil.

Plastic to Oil Machine: A Green Chameleon?

The pivotal question that looms large is whether these plastic to oil machines can truly earn their green credentials. Let’s dissect the various facets that underscore their potential environmental impact.

1. Resourceful Resurgence

The undeniable advantage of plastic to oil machines lies in their ability to revive seemingly irredeemable plastic waste. Plastic pyrolysis opens a gateway to a circular economy, where discarded plastics find a new life as a valuable resource rather than languishing in landfills or drifting as oceanic flotsam.

2. Mitigating Carbon Footprint

In the grand tapestry of environmental conservation, carbon footprint reduction takes center stage. Plastic to oil machine, through their innovative pyrolysis process, offer a ray of hope. By converting plastics into oil without the need for combustion, these machines sidestep the conventional emissions associated with traditional plastic disposal methods.

3. Economic Viability

Beyond ecological considerations, the economic viability of plastic to oil machines adds another layer to their allure. The synthesized oil can serve as a raw material for various industries, contributing to a more sustainable and economically robust future.

Challenges on the Horizon

However, navigating the landscape of sustainable technologies is seldom a seamless journey. The plastic to oil dream encounters its share of challenges, demanding a nuanced examination.

1. Technological Maturity

The efficacy of plastic to oil machines hinges on the technological maturity of the pyrolysis process. Achieving a delicate balance between efficiency and environmental impact poses a formidable challenge that necessitates ongoing research and development.

2. Feedstock Composition

The heterogeneous nature of plastic waste introduces an element of complexity. The efficacy of pyrolysis is contingent on the composition of the plastic feedstock, and optimizing the process to accommodate diverse plastics remains a persistent challenge.

3. Economic Dynamics

While the economic potential of synthesized oil is tantalizing, the economic viability of large-scale or small plastic recycling machine demands scrutiny. Initial setup costs, operational expenses, and market dynamics all play pivotal roles in determining the true green credentials of these machines.

The Road Ahead: Nurturing Green Credentials

In the quest to establish the green bona fides of plastic to oil machines, a multifaceted approach is imperative.

1. Technological Advancements

Investing in research and development is paramount for enhancing the efficiency and environmental performance of plastic pyrolysis. Technological advancements hold the key to unlocking the full potential of these machines and addressing existing challenges.

2. Regulatory Framework

A robust regulatory framework is essential to ensure that the deployment of plastic to oil machines aligns with stringent environmental standards. This includes monitoring and controlling emissions, waste management, and ensuring the overall ecological footprint remains within acceptable limits.

3. Public Perception

The success of any green initiative is intricately linked to public perception. Raising awareness about the potential of plastic to oil machines in mitigating plastic pollution and contributing to a circular economy is pivotal for garnering support and fostering a culture of sustainability. Curious to know more? Visit Beston Group for a comprehensive look at what we have to offer.