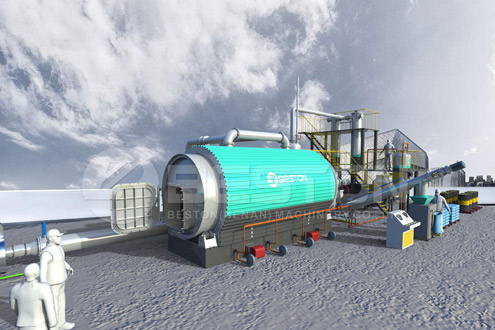

Recycling is a lot more common than it used to be. There are recycling programs all over the country. Materials that once would have wound up in a landfill are now being recycled in a variety of ways. Because of this, you might want to invest in some sort of rubber pyrolysis plant, such as rubber recycling equipment. Here’s why this kind of equipment is a wise buy.

There’s A Lot Of Rubber That Can Be Recycled By Rubber Recycling Equipment

It shouldn’t be difficult for you to get materials that you’ll be able to use in your waste pyrolysis machine for sale. There is a lot of rubber waste that’s available. You might be able to get this waste for free, or you may be able to get it for a fair and reasonable price. See the tyre pyrolysis process.

Since it’s easy to get the rubber that you need, recycling shouldn’t be an issue for you. When you’re putting money into a recycling plant, you’ll want to make sure you’re getting something that will work for you.

Recycling Equipment Is More Affordable Than It Used To Be

In the past, you might have had to invest a great deal of money in order to buy a recycling plant. While this is still a significant purchase, there’s a good chance that you’ll be able to get the plant that you need for less.

You should look at the cost of the equipment that you need. Once you see what you can do with your money, you’ll be able to decide if this is a wise investment for you. You may find that recycling equipment is a great buy.

Since you’ll be able to find a lot of affordable options, it will be easier for you to profit off your plant. Your upfront costs should be manageable, and it’s likely that your costs over time will also be fairly reasonable. For more info here: http://seepas.mee.nu/.

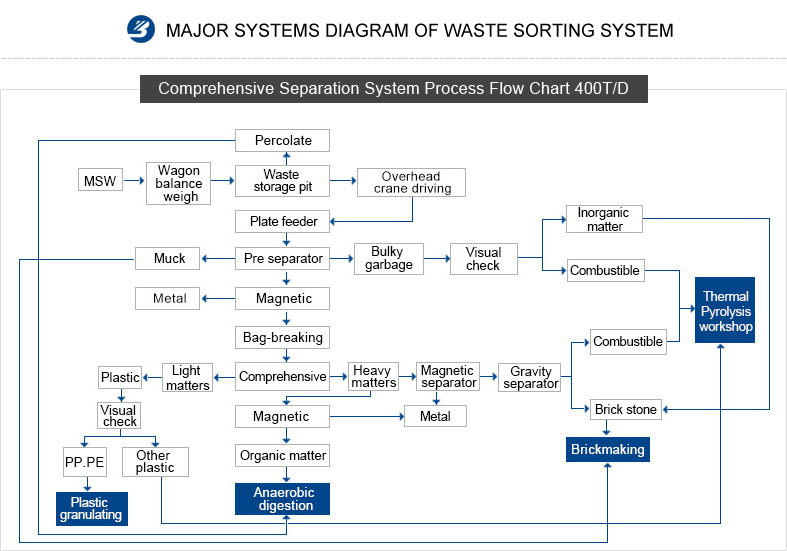

Rubber Can Be Converted Into Many Valuable Materials

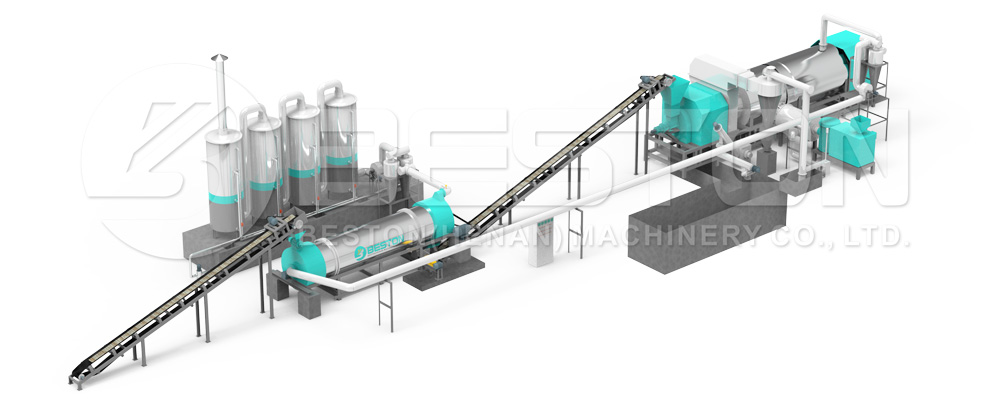

It’s possible to convert rubber into a number of materials that are valuable and useful. For example, you could turn rubber goods into new goods that can be sold. It’s also possible to turn rubber into oil through the process of pyrolysis.

There are a lot of things that you can do with rubber, which means you’ll have a lot of control over your plant. You should look at some of the things you can do with rubber and make decisions about what you want to do with your plant.

There are many benefits to investing in rubber recycling equipment. If you do spend money on this equipment, you’ll be able to earn back most of the money that you spend. This equipment can pay off for you in a big way.

When everything is said and done, you’ll have to decide whether or not you’re comfortable investing in rubber recycling equipment. However, when you look at all of the advantages that this sort of equipment can offer, you’ll be able to see that it can be a great buy. Think about buying equipment like this in the future. Get the waste to energy plant price from a reliable manufacturer, Beston Group.