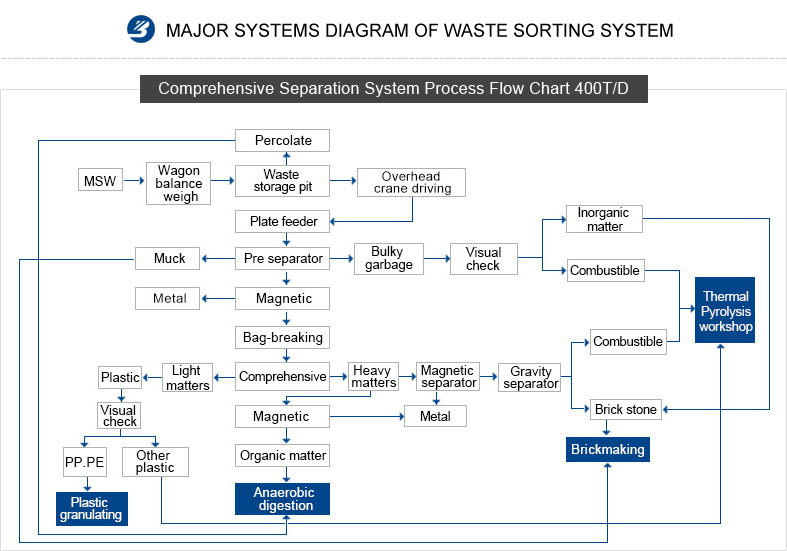

Urban solid waste management (planta de tratamiento de residuos solidos urbanos) is one of the biggest challenges of most cities in the civilized world. We all produce a lot of garbage on daily basis, as most products come in boxes and wraps we have to dispose of one way or another. Fortunately, part of this waste can undergo a recycling process to be turned into useful stuff.

The recycling process requires that solid waste is separated into the main categories of materials. This is the biggest challenge of waste recycling plants, as they require special devices and equipment to extract various materials and send them to different processing lines. Whatever can’t be recycled will end up in landfills. The biggest challenge of garbage sorting plants is to minimize the amount of waste they send to landfills.

The first thing to consider is that most garbage arrives to the waste management plant in plastic bags. Someone has to remove these bags in order for the garbage to enter the sorting process. Some operators choose to hire manual workers to remove the bags. However, this method isn’t the cheapest or the most accurate of all. This is why smart companies choose an automatic plastic bag removing equipment which can do this job much faster and much better than humans. There will always be some workers to watch over the process and to correct faults, but the whole process (separador de residuos solidos) would cost a lot less.

The other thing to keep in mind is that different types of waste require different types of conveyor systems. While heavy items require metallic conveyor belts, everything else can be just find with traditional rubber belts. The nature of the materials will also influence the size and the speed of these conveyor systems. As they are one of the very important links of the waste management process, conveyor systems require special attention and careful design.

All urban solid waste sorting plants (residuos solidos clasificacion) will have a metal extractor. This tool is nothing else but a giant and powerful magnet that extracts metal waste from the bulk and sends it to a special conveyor to enter the compacting process. In order to extract the copper, plants require another machine which generates a magnetic field that does the job.

There are two types of plastic waste: recyclable and non-recyclable. As you can easily imagine, they also need separation. This is easy to achieve with the help of a centrifugal drum machine with holes of different sizes. Such devices base their effectiveness on the different specific weights of the different types of plastic materials.

Last but not least, compacting is one of the steps of the solid waste management process. It is very important because it can make waste more manageable by reducing its volume and by molding it into a shape that’s easier to handle and to store. This can help cutting the costs with transporting the waste to the next stages of the recycling process.