You’ve got your mind set on a tire recycling plant, and you’ve been hearing about how businesses are profiting from them. You need to know exactly what to expect, and you’re wondering if this type of investment fits your company. You certainly have rubber waste or you wouldn’t be considering this opportunity. Yet it does behoove you to make sure that such a substantial investment is in the cards.

You want to know that after your investment, you are able to start making your money back quickly. This is going to require that you have enough waste to feed the rubber recycling plant daily, and that is going to mean that you do some calculations. These calculations should be easy enough for you to do because you know your business well. You’re going to want to figure out the numbers on the other end though.

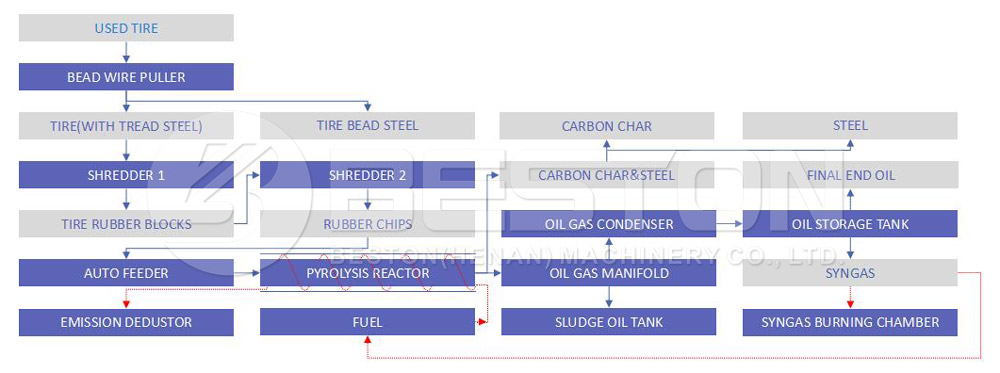

What do I mean by the numbers on the other end? Let’s say that you recycle x amount of waste daily. You want to know about how much steel, carbon black, pyrolysis oil and gas you’re going to net each day. You also want to know how much you are going to be able to charge for those substances. You can then compound those days to determine at what point you are able to pay the pyrolysis machine off.

You can imagine that after you pay the machine off, you’re able to count on those daily profits without any other expenses, save for maintenance or paying people to operate the machine. People do have to oversee the machine of course, to a degree. And if you buy a pyrolysis batch plant, you’re looking at a little more work. You can purchase a continuous pyrolysis plant, but you have to make sense out of that large of an investment. Click here to know more about Beston Machinery.

If you have a lot of waste tires built up right now, you’re going to be clearing out that space soon enough. And just think about how your profits are going to skyrocket from the get go with all that waste ready to recycle. Who knew that you could make that kind of money by recycling waste tires? Get pyrolysis plant cost here.

You’re going to be putting a lot of waste rubber through the pyrolysis process. It’s going to be nice to see the companies buying the carbon black, pyrolysis oil and steel off of you. You’re going to want to maintain good reporting for this side business venture, and you can celebrate once you reach profitability. Right now, you’re slated with getting in touch with a reputable manufacturer so that you can get a pyrolysis machine for sale set up on location.